PFA Fluoropolymer FILM

PFA film is a transparent, thermoplastic film that can be heat sealed, thermoformed, vacuum formed, heat bonded, welded, metalized, laminated (combined with dozens of other materials), and used as an excellent hot-melt adhesive. This wide variety of fabrication possibilities combines with the following important properties to offer a unique balance of capabilities not available in any other plastic film.

![]() Product Feature:

Product Feature:

· Continuous service temperature : -240 to 260℃(-400 to 500℉)

· Melting range:300to 310℃(572to 590℉)

· Heat sealable

Chemical Resistance:

· PFA film is stable to almost all chemicals and solvents. It also has low permeability to liquids, gases, moisture, and organic vapors.

· It also has low permeability to liquids, gases, moisture, and organic vapors.

Flame Resistance

· PFA films is flame retardant material with limited oxygen index (LOI) > 95%.

Weather Resistance:

· PFA film can withstand long-term outdoor exposure without changing its performance.

· High transmittance of ultraviolet and all, but far, infrared.

Mechanical Toughness

· Superior anti-stick and low frictional properties.

· High resistance to impact and tearing.

Electrical properties

· High dielectric strength, over 250 kV/mm for0.025-mm film

· No electric tracking, non-wettable, and non-charring

· Very low dielectric constant, dissipation factor, and stable temperature change among solid insulating materials.

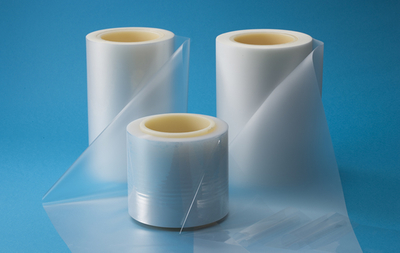

![]() Table 1: Typical Properties of QMT PFA Fluoropolymer Film:

Table 1: Typical Properties of QMT PFA Fluoropolymer Film:

|

Items |

Unit |

Value |

|

Gauge |

μm |

10-500 |

|

Width |

mm |

50-1600 |

|

Density |

|

2.15 |

|

Melt Point |

℃ |

300-310 |

|

Continuous Service Temperature |

℃ |

260 |

|

Tensile Strength(MD/TD) |

Mpa |

54/50 |

|

Elongation at break (MD/TD) |

% |

430/450 |